INTRODUCTION

Contrary to legend, the first American gold rush did not begin in California. It actually started in North Carolina and quickly escalated after a major gold strike near Dahlonega, Georgia in 1828. Excitement and would-be prospectors followed the gold from Georgia to California to Colorado, and later to North Dakota and Alaska. Unprecedented sources of silver in Nevada and Colorado added to the mining frenzy that finally made the United States self-sufficient in precious metals.

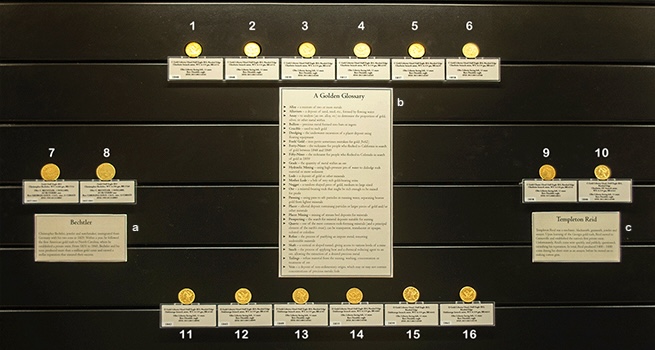

Thousands of prospectors staked claims, straining each region’s economy and creating coin shortages. New facilities were needed to smelt, refine and assay the newly discovered gold. By 1830, local assayers such as Templeton Reid and the Bechtlers produced private gold pieces – far more convenient than dust, nuggets or ingots of varying fineness and weight. In 1838, the U.S. Mint founded branch mints at Dahlonega, GA and Charlotte, NC to strike coinage on site with local gold, ending the private gold issues. Both branches struck $1, $2.50 and $5 gold coins until the Civil War.

Did You Know?

Gold nuggets are usually found in rivers and streams, along with other erosional debris. Naturally formed clusters of gold crystals, nuggets are weathered out of an original vein or lode. Purity can be assessed by the nugget color. The deeper the yellow-orange color, the higher the gold content.

Click on the items in the case image below for an enhanced view

|

AUDIO COMPANIONS

|

The greatest challenge encountered in any gold rush is the shortage of supplies and, ironically, money. American gold rushes all occurred in relatively unpopulated areas, poorly equipped to handle large numbers of prospectors. The infrastructure for processing raw gold was generally non-existent: assayers, smelters, mining supplies and even reliable cash to buy equipment all had to be imported. Most prospectors, hoping to strike it rich, arrived with little money and no consideration of how to cash in on their finds. Shopkeepers needed to determine the value of gold dust or nuggets, requiring the development of an assay system to create a functioning market.

Assaying – the analysis of a metal to determine its components and purity – required scientific expertise. Over 24 hours, assayers melted raw gold, refined it, and molded the molten metal. Once cooled, the assayer would – hopefully – take an honest fee from the bullion before stamping the purity, weight, serial number, and exact U.S. dollar value onto the piece. A successful assayer needed an unblemished reputation, his word “as good as gold.”